Depending on the size and age of your public water system, completing the lead service line inventory may feel like one of the most labor-intensive regulatory compliance efforts your water system has ever undertaken.

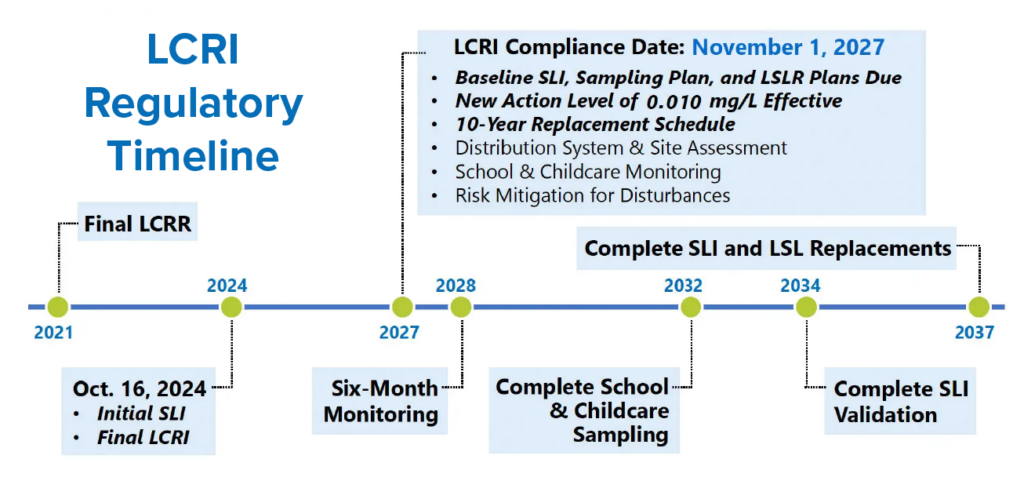

Under the U.S. Environmental Protection Agency’s (USEPA) Lead and Copper Rule Improvements (LCRI), water systems have less than two years to complete their baseline service line inventories and create service line replacement plans for all lead and galvanized requiring replacement service lines identified within the system. The baseline inventory, which includes connectors under the LCRI, must be submitted by November 1, 2027.

There are many ways to gather the information needed to fill out the inventory. How many of the following methods have you employed to date?

Check Historical Records

A great place to start is by looking up the date a lead pipe ban went into effect locally – whether at the State, county, or city level. Once the date is known, review aerial imagery of the service area from before and after the ban. This method can tell you where lead pipes are unlikely to be found based on construction occurring after the ban was instituted.

AE2S project managers begin each LCRI effort by requesting historical plans and specifications from clients, as well as building and plumbing code documents to review. When records are available, AE2S staff have had great success identifying the materials utilized in the construction of utility infrastructure and privately owned service lines. Though it takes time, record review has the potential to identify large swaths of a service area when records name the required pipe materials.

Survey Your Customers

Asking your customers to complete a short survey is one of the most cost-effective and time-efficient ways to gather data for your service line inventory. However, one thing we have learned through the service line inventory process is that a good share of the public does not know what a service line is or where it can be found. Therefore, it is imperative that a robust customer education campaign deployed in conjunction with a survey. The campaign should include several of the following tactics:

- Personalized letters or mailers

- Town hall events

- Billing inserts

- Website announcements

- App or text alerts

- News releases

- Advertisements or Public Service Announcements (PSA)

The following information should be included with each survey request:

- WHY the water system is looking for lead pipes, plus the health concerns associated with lead in drinking water

- WHAT a service line is

- WHERE a service line can typically be found

- HOW to identify lead, copper, plastic, and galvanized pipe materials

- WHEN survey responses are due

- WHO to contact for assistance

A major benefit of digital surveys that can be accessed via QR code or web address is the dramatic reduction in manual data entry. “Our team developed a survey within the ArcGIS program that automatically feeds customer responses into a database and map of the client’s service area,” says Lucas Rengstorf, AE2S Lead GIS Specialist. “The map identifies pipe materials on both the public and private sides of a service line using designated colors that represent unknown, lead, galvanized, and non-lead pipes. The map can also help a water system identify neighborhoods where lead pipes are more common and highlight neighborhoods where additional public outreach could be beneficial to increase survey response rates.”

Another digital survey benefit is that photos can be uploaded to allow customer pipe identifications to be confirmed by experts. Some States, like North Dakota, require photos of service lines that have been identified by customers. AE2S staff consider the photo requirement a best practice because it creates a record that water system personnel and regulatory agencies can review in the future.

A drawback to digital surveys is that not everyone has access to the internet or familiarity utilizing QR codes. This lack of access or familiarity can make online surveys challenging to complete for some segments of the population. The low-tech nature of paper surveys means more people can easily complete them. However, the challenges to utilizing paper surveys include the amount of data entry required, as well as the physical space or digital storage capacity needed to scan and save completed paper surveys.

Some utilities accept survey responses and photos via email or text messages, which effectively reduces the need for utility staff to sort through stacks of paper and scan printed photos. However, these methods unfortunately do not reduce the amount of data entry required to add the information to an inventory.

Conduct Inspections

If a water system has the time, budget, and staffing to do so, conducting door-to-door inspections can be an effective way to complete a service line inventory. AE2S has deployed staff members to complete inspections on behalf of our clients.

“We have found door-to-door to be most effective when inspectors can make the rounds at varying times of day, including evenings and weekends. Leaving door hangers with contact information for customers to make an appointment is also a good idea if your system has the capacity to take phone calls and schedule appointments,” says Christine Lidenberg, AE2S LCRI Project Manager.

Even if your system does not have a staff or budget that can accommodate door-to-door inspections, it should become a standard practice to identify the service line any time utility staff visit a home or business. In addition, some utilities moved up water meter and water main replacement projects to occur simultaneously with the service line inventory. This allows pipe materials to be documented by staff and contractors as the replacement project is underway.

Finally, potholing may be employed as a last resort if the water system is unable to access a service line any other way. This is one of the most disruptive inspection options, as it involves disturbance to lawns, sidewalks, or public streets to view and identify both sides of the service line. If the water system does not have its own equipment, it can be costly to hire a contractor to pothole and restore property to its previous state.

Minimum Service Line Material Verification Process

Predictive modeling is another way to help complete a service line inventory, in States that allow the method. AE2S has performed the Minimum Service Line Material Verification process, also known as predictive modeling, in Utah. The method uses probability to identify the likelihood of specific service line materials being installed in a water system. The process followed in Utah and Colorado allows water systems to randomly select and verify a portion of unknown service lines instead of physically identifying every single service line. The following paragraphs briefly describe the Minimum Service Line Material Verification Process in Utah and Colorado.

The first step is to create a list of confirmed service line materials. If records exist or physical verification has been completed, a service line can be considered confirmed or “known.” A second list of “unknown” service lines should be created – this list can include any service lines that have not yet been confirmed and those for which the water system has no information.

Under the Minimum Service Line Material Verification process, public water systems with fewer than 1,500 unknown service lines must physically verify at least 20% of the total number of unknown service lines. For systems with more than 1,500 unknown service lines, enough lines must be physically verified to reach a minimum 95% confidence level. The Utah Division of Drinking Water has a table in the Lead Service Line Inventory Guidance (pages 31 and 32) that identifies the exact number needed to be verified based on a water system’s total number of unknowns. For example, 322 unknown service lines must be physically verified if a water system has 2,000 total unknowns.

Random selection must be utilized to create the list of unknown service lines that will be physically verified. The Utah Division of Drinking Water walks through the instructions for successful randomization to ensure the list of unknowns is truly random and unbiased.

“Since there is no guarantee that every property that is randomly selected will provide access to inspect service lines, we recommend adding additional sites to the unknown list to be physically verified. Having extra properties on the randomized list will allow the water system to reach its goal if access to some is not granted,” explains Dan Lissick, AE2S GIS Project Manager.

Under the Minimum Service Line Material Verification process, if no lead service lines were found during the predictive modeling process AND there are no records or knowledge of lead service lines or lead service line replacements, a water system is allowed to classify all its unknowns as non-lead. However, if lead or galvanized requiring replacement service lines are identified during the predictive modeling process, all the sites within the system’s service area with similar attributes are to be categorized as unknown until they can be physically verified.

Multi-Prong Approach is Best

Over the past three years, AE2S has been working with many water utilities in North Dakota, South Dakota, Minnesota, Montana, Colorado, and Utah to complete their service line inventories. We have discovered there are several ways to gather data, and a multi-prong approach is the most effective. If you have questions or need assistance with your system’s LCRI compliance, contact Nate Weisenburger, AE2S Drinking Water Practice Leader for assistance.